Our Capabilities

Cutters Foam Fabricating has a large variety of machinery, methods, materials, and skilled employees to ensure that we can create whatever you need.

Design

We offer a variety of services to make things easier for our customers.

Cutters Foam Fabricating has over 60 years of combined foam experience in the R&D department. We always consider your application along with the price point in order to exceed your expectations.

Prototyping

We're extremely versatile when creating new products for our customers.

We can work with DXF files, reverse-engineer an existing part, or start with nothing more than a sketch and frame measurements. We're here to help you bring your vision to life.

Quality Assurance

Cutters Foam Fabricating can assist in maintaining adherence of raw materials to the correct specifications.

Our processes help you save time, money, and headaches.

The Process

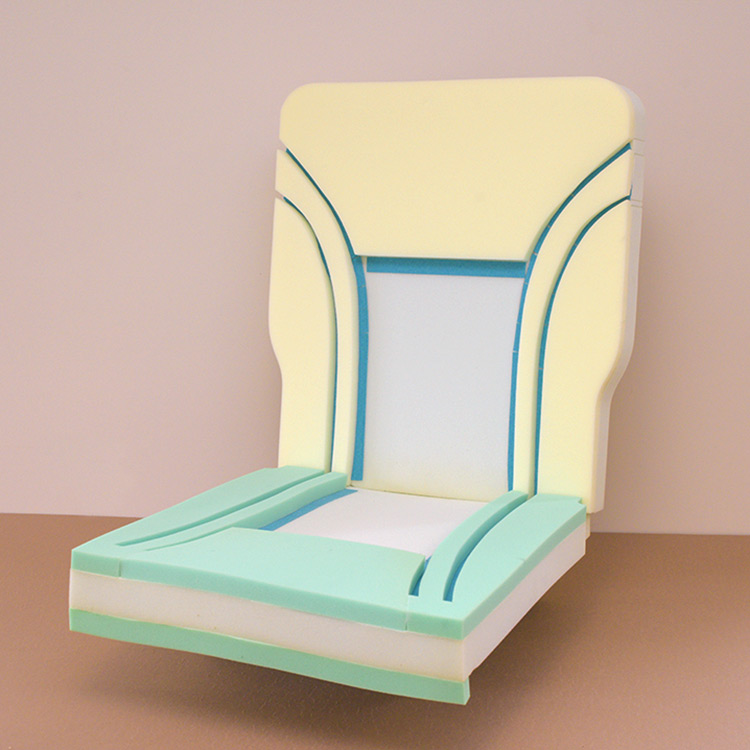

Adhesive lamination allows us to build multi-density constructions which are not achievable with molded foam. Work can be as simple as a 2-layer cushion or as complex as a 3-dimensional captain’s chair utilizing multiple foam grades.

Used for:

Cutter’s Foam can laminate Velcro hook to the foam to allow hook & loop style of upholstery. We can also laminate steel or wood to the foam for arms or headrests.

Description:

Used in:

Polyurethane Foam

pliable, light weight, open-cell foam; provides comfort & support at reasonable cost

furniture cushions, mattresses, automotive seating, medical applications

Polyethylene Foam

more rigid, light weight closed-cell foam; it is durable, chemical & moisture resistant, mold & mildew resistant

packaging, returnable dunnage, case inserts

Cross-linked PE Foam

chemically cross-linked variety of polyethylene foam; smoother feel than standard PE foam; ability to protect Class ‘A’ surfaces

medical device packaging, case inserts

Reticulated Foam

porous, extremely open-cell structure polyurethane foam; it is lightweight and mildew resistant, chemical resistant

outdoor furniture cushions, air filters, liquid filters, marine seating

Memory Foam (viscoelastic)

soft, temperature sensitive foam that molds to the shape of a body; slowly recovers to original shape when pressure is removed

mattresses & pillows

High Resiliency Foam

higher density, open-cell polyurethane foam with more random cell structure; greater support & durability; fast recovery, quickly bounces back to original shape

residential furniture, hospitality furniture, medical furniture & positioning cushions

Anti-Microbial Foam

polyurethane foam with additives to inhibit the growth of bacteria, fungi, mold & mildew

marine seating, outdoor furniture cushions

Convoluted Foam (egg-crate)

polyurethane foam that goes through a special cutting process; offers better airflow

mattresses, case inserts

Rolls

we stock Remay rolls, non-laminated rolls, fiber rolls

Dacron Fiber

polyester fiber; hypoallergenic, non-absorbent, mildew resistant

surface wrap over the foam core of furniture cushions

Densified Fiber

Dacron polyester fiber that is compressed to create a higher density per cubic inch; more supportive than standard Dacron fiber

surface wrap over the foam core of furniture cushions